|

| August 22, 2023 | Volume 19 Issue 32 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Conductive Brush Ring overcomes current leakage in EV powertrains

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

Learn more.

Intro to reed switches, magnets, magnetic fields

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

View the video.

Bi-color LEDs to light up your designs

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Learn more.

All about slip rings: How they work and their uses

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Read the overview.

Seifert thermoelectric coolers from AutomationDirect

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Learn more.

EMI shielding honeycomb air vent panel design

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Read the Parker blog.

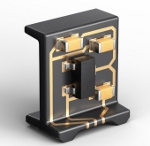

What is 3D-MID? Molded parts with integrated electronics from HARTING

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

Loss-free conversion of 3D/CAD data

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

Learn more.

Top 5 reasons for solder joint failure

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Read this informative ANSYS blog.

Advanced overtemp detection for EV battery packs

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Learn more.

Benchtop ionizer for hands-free static elimination

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

Learn more.

LED light bars from AutomationDirect

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Learn more.

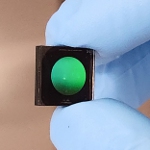

World's first metalens fisheye camera

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

Learn more.

Orbex offers two fiber optic rotary joint solutions

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Learn more.

Mini tunnel magneto-resistance effect sensors

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Learn more.

Pivotal discovery in sensor tech combats water contamination and more

Major step toward large-scale manufacturing of uniform and reliable smart sensors for real-time monitoring of multiple constituents in water.

By Joseph E. Harmon, Argonne National Laboratory

There is a global water crisis, and it is not only about the dwindling supply of clean water. Contaminated drinking water exposes hundreds of millions of people worldwide to toxins, such as bacteria, heavy metals, pesticides, and viruses. This contamination imperils public health and can cause serious illnesses.

A team of researchers from the U.S. Department of Energy's Argonne National Laboratory, along with the Pritzker School of Molecular Engineering at the University of Chicago and the University of Wisconsin - Milwaukee, has devised a pathway for the mass manufacture of sensors able to simultaneously detect lead, mercury, and E. coli. in flowing tap water. The team's innovation promises to help safeguard public health by providing early warning for contamination.

"Traditionally, sensors designed to measure contaminants in water have suffered from reliability issues and the inability to detect faulty devices," said Argonne scientist Haihui Pu, who holds a joint appointment with UChicago's Pritzker Molecular Engineering. "Improved sensors could avert health crises."

Artistic rendering of water sensor with graphene-based nanolayer and two electrodes attached at top. Alternating current voltages at varying frequencies (wavy lines) are used to rapidly and non-destructively screen for high-quality sensor devices. [Credit: Image by Argonne National Laboratory]

At the core of these sensors lies a one-nanometer-thick layer of carbon and oxygen atoms, a form of graphene, which is coated on a silicon substrate. This graphene material serves a similar purpose to the semiconductors found in computer chips. Gold electrodes are then imprinted onto the graphene surface, followed by a nanometer-thick insulating layer of aluminum oxide. Each sensor is tailored to detect one of the three toxins: lead, mercury, or E. coli.

One of the major challenges in mass manufacturing these sensors has been assessing their quality. Tiny areas of undesired porosity can form in the ultra-thin insulating layer. This porosity allows electrons from the bottom graphene layer to escape into the top insulating layer. This leakage compromises its effectiveness as an insulator and results in unreliable sensor responses.

The team's recent publication in Nature Communications describes a screening method to identify defective devices before mass production. The method involves measuring the electrical response of the insulating layer while the sensor is submerged in water. Key is that the screening does not damage the sensor. By employing this technique, the team identified structural defects in the insulating layers. They were then able to establish criteria to easily detect faulty devices.

To demonstrate the efficacy of their approach, the team evaluated a three-sensor array able to simultaneously detect lead, mercury, and E. coli in flowing tap water. Using machine learning algorithms to analyze the results, they were able to quantify toxin levels down to the parts per billion, even in the presence of interfering elements.

"The beauty of the sensors is that you can apply them in any form of water, not just tap water," said Junhong Chen, Argonne's lead water strategist and Crown Family Professor at Pritzker Molecular Engineering. "What's more, you can combine three, thirty, or three hundred sensors, with each tailored to detect different constituents." These include not only heavy metals and bacteria, but pharmaceuticals, pesticides, coronaviruses, and a common contaminant in water, per- and polyfluoroalkyl substances. They might also include critical resources, such as cobalt for batteries and nitrogen and phosphorus as nutrients for plants and animals.

Once problematic or valuable elements are identified and removed, the sensors can be used to assess the cleanliness of treated water. The results can guide the safe reuse of the water, including potable use, agriculture and irrigation, groundwater replenishment, and industrial processes.

Chen expressed hope for commercializing this technology through a startup company he founded.

The team's screening method offers a versatile tool for monitoring water quality and optimizing its safe reuse. As scientists tackle this critical issue, their efforts serve as a beacon of hope for a healthier, more sustainable future.

Published August 2023

Rate this article

View our terms of use and privacy policy